Manufacturing

Agro Plantation

Mining

Retail

Logistics

Healthcare

Education

Travel & Hospitality

Step into the future of manufacturing

Unleash the power of AI and data with our Smart Factory solutions.

Elevate your production capabilities with SIM 4.0, where innovation meets efficiency.

Our cutting-edge automation solutions redefine the manufacturing landscape, ensuring a seamless transition into the era of Industry 4.0.

Is your factory still running on outdated manual processes, limiting your efficiency, scalability, and profitability in today’s competitive manufacturing landscape?

![]() Struggling with quality control issues that slow down output and risk customer dissatisfaction?

Struggling with quality control issues that slow down output and risk customer dissatisfaction?

![]() Losing precious hours to reactive maintenance and unplanned downtime, disrupting your entire production line?

Losing precious hours to reactive maintenance and unplanned downtime, disrupting your entire production line?

![]() Finding it difficult to compete as others embrace automation and real-time efficiency tracking?

Finding it difficult to compete as others embrace automation and real-time efficiency tracking?

![]() Dealing with fragmented systems that make it hard to monitor operations and workforce productivity?

Dealing with fragmented systems that make it hard to monitor operations and workforce productivity?

![]() Facing inconsistencies in compliance & traceability, impacting audit readiness & process reliability

Facing inconsistencies in compliance & traceability, impacting audit readiness & process reliability

![]() Experiencing delays in production planning and execution due to manual data flows

Experiencing delays in production planning and execution due to manual data flows

![]() Unable to gain real time insights, leading to poor decision making and missed opportunities.

Unable to gain real time insights, leading to poor decision making and missed opportunities.

![]() Falling behind in the Industry 4.0 race while your competitors move toward intelligent data-driven manufacturing

Falling behind in the Industry 4.0 race while your competitors move toward intelligent data-driven manufacturing

Revolutionize manufacturing with SIM4.0

Elevating productivity by 30%, reducing downtime by 25% and optimizing processes with real-time analytics.

Join the Industry 4.0 evolution for smarter, efficient, and data-driven production.

– Softweb SIM 4.0

SIM4.0 – Smart Intelligent Manufacturing for next generation Factory

Smart Intelligent Manufacturing or SIM 4.0 is the amalgamation of physical technology with digital technology to make optimum utilization of resources leading to achieving production efficiency and business growth. SIM 4.0 involves the usage of Artificial Intelligence (AI) along with cloud computing and the Internet of Things (IoT), Machine Learning (ML), Robotic Process Automation (RPA) helping in streamlining the three major components of production and supply chain-Machine, Process & People.

Smart Manufacturing System

Are You Future Ready with SIM 4.0 ?

Is your manufacturing unit falling behind in this competitive world? If you have not implemented smart factory automation you are already behind the curve. As competitors are gaining market share through on-time delivery and optimized production, not implementing SIM 4.0 will eventually lead to a loss of market share. By not implementing SIM 4.0, there is always a risk of lower productivity, more errors and higher costs-leading to erosion of profit and even business failure.

SIM 4.0 enables your factory assets to be synchronized, responsive, adaptive, optimized, predictive, agile, transparent and proactive generating real-time data for businesses to take real-time decisions. SIM 4.0 helps you see the future, by accurate predictions based on benchmark vs actual data. It helps you get a 360-degree view of entire business units right at your fingertips.

Smart Intelligent factory, once implemented has shown a growth of 7% annually with even doubling the operating profits. Results have shown Digital masters, or units which have adopted Sim 4.0 early have nearly doubled their profit as well as recovered their costs within the first five years compared to laggards, who have still not implemented SIM 4.0 and have yet to recover their operating costs.

This is because SIM 4.0 helps you benchmark and set trends and track the value of critical parameters. Any deviation from set values is recorded and reported along with the times it occurred. The adept prediction regarding production could be done helping you to plan orders and delivery accordingly helping increase client trust and revenue growth.

Have you ever felt your line managers are not at par with higher management goals? or the bottlenecks faced by them inaccessible to higher management? Thanks to SIM 4.0, it assists every level of Managers and supervisors from the shop floor to higher management with customized and consolidated reports for every level. Be it line managers, Mid managers or higher management- with seamless data flow through SIM 4.0, everybody can access and analyze the production, Consumption (energy, fuel) or KPI deviations initializing problem-based solutions in real-time.

SIM 4.0 is enabling industries of every size to confront major production barriers resulting in revenue growth and expansion and maintain their BCP (Business Continuity Plan) aiding control.

Salient Features

IoT Enabled

IoT Enabled Sensors helping faster Data capture & analysis

KPI Tracking

Accurate tracking of KPIs for both machine & people

Recognize Bottlenecks

Identify bottlenecks in process for quick redressal

Real-time production data

Automated Alerts for production downtime or other anomaly

ERP Integration

Aligning Operations with Business Goals

Weighment process Automation

Automatic entry of weightment with zero manual intervention

Device Connectivity

Connecting smart devices & technologies

Data Warehousing

Storing and Using accurate information

Business Intelligence & Monitoring

Actionable Insights on live operations data

How SIM 4.0 helps you?

– Access real-time data.

– Reduce wastage in production.

– Weighment process automation.

– Live KPI Tracking.

– Recognize Bottlenecks comparing benchmarks for quick redressal.

– Predictive analysis of machine production.

– Data Protection and privacy.

– Zero Manual Intervention at data entry point.

Softweb makes SIM 4.0 easy

– Assess Conditions to Develop a tailor-made strategy.

– Streamline Management System.

– Identify bottlenecks for quicker resolution.

– Live tracking of Key Performance Indicators (KPI).

– Facilitates accurate order processing.

– Round-the-clock support for smooth implementation.

– Develop manufacturing intelligence vision for future growth.

– Transform Your Factory Today! –

Get Started In Three Simple Steps

Understanding Scope

Understanding business process and identification of key areas

Solution Implementation

Implement our solution seamlessly in your business enterprise

Success Unravels

Unravel your journey towards business growth & customer satisfaction with Softweb

Our Testimonials

What some of Our Clients saying

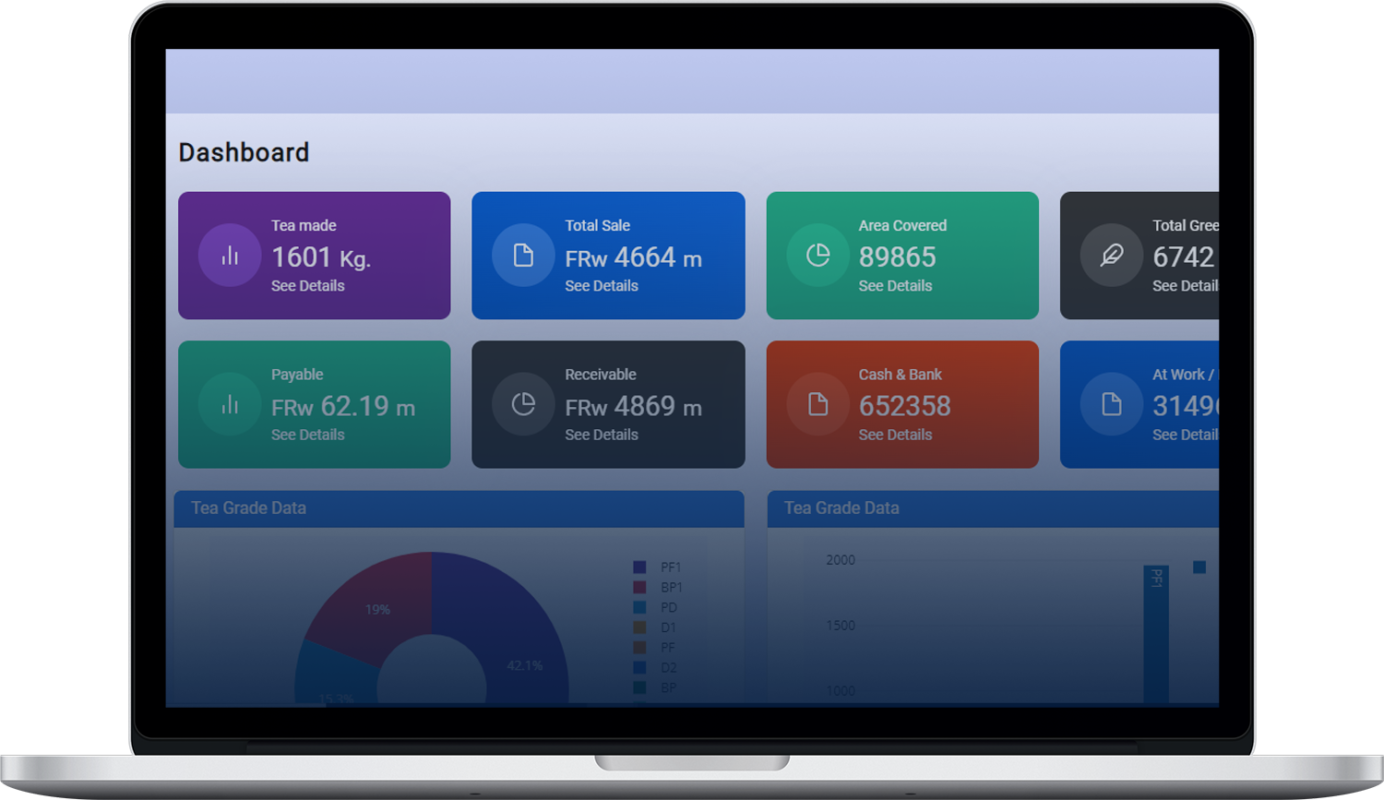

– Real-Time Data Analysis

SIM 4.0 Dashboard

Softweb’s SIM 4.0 has developed an easy-to-interpret and user-friendly Dashboard. Every data is represented both in tabular form as well as interactive charts and graphs allowing users to quickly comprehend the data for deeper and better analysis. SIM 4.0 provides a holistic view of operations on a real-time basis, ensuring management makes timely and informed decisions based on accurate and authentic data.