Manufacturing

Agro Plantation

Mining

Retail

Logistics

Healthcare

Education

Travel & Hospitality

ERP software for the textile, apparel and garment industry optimizes your entire business process from start to finish. It operates on a unified database platform, allowing different departments to communicate and collaborate effortlessly with complete overview of the business.

Textile ERP software enhances management in key areas of the textile industry, such as raw materials, finance, inventory, quality control, plant management, sales and lot more. PACE360 seamlessly integrated, enabling smooth interaction between all parts of the business.

Textile manufacturing involves complex processes, including procurement, production (Spinning, weaving, finishing), distribution, vendor management, despatch. Quality control in raw material as well as finished product is also crucial.

Given the complexity, PACE360 is a well-planned ERP solution designed for textile, garment and apparel manufacturers to confidently compete on the global stage.

Process of Textile, Apparel and Garment Manufacturing

Primarily Textile manufacturing

could be broadly categorized under:

– Spinning

– Weaving

– Processing

– Finishing

Book a Call

Spinning:

Spinning transforms raw fibers into yarn by twisting them together. This process creates a strong, continuous thread that forms the foundation for weaving or knitting, ensuring the fabric’s durability and quality.

Weaving:

![]() Warping: Warping involves arranging yarns parallel on a beam to prepare them for weaving. This step ensures consistent tension and alignment, setting the foundation for smooth fabric production.

Warping: Warping involves arranging yarns parallel on a beam to prepare them for weaving. This step ensures consistent tension and alignment, setting the foundation for smooth fabric production.

![]() Sizing: Sizing coats yarn with a protective layer, enhancing its strength and reducing breakage during weaving. This process is crucial for maintaining yarn quality and improving weaving efficiency.

Sizing: Sizing coats yarn with a protective layer, enhancing its strength and reducing breakage during weaving. This process is crucial for maintaining yarn quality and improving weaving efficiency.

![]() Weaving: Weaving is the process where yarns are interlaced on a loom to create fabric. This intricate method defines the fabric’s texture, pattern, and strength, forming the core of textile manufacturing.

Weaving: Weaving is the process where yarns are interlaced on a loom to create fabric. This intricate method defines the fabric’s texture, pattern, and strength, forming the core of textile manufacturing.

![]() Inspection & Stocking (Weaving): After weaving, fabrics undergo inspection to identify and rectify any defects. Once approved, they are carefully stocked, ready for further processing or distribution.

Inspection & Stocking (Weaving): After weaving, fabrics undergo inspection to identify and rectify any defects. Once approved, they are carefully stocked, ready for further processing or distribution.

Processing:

![]() Production Plan: A production plan outlines the entire manufacturing process, ensuring that every step, from raw material sourcing to final product delivery, is executed efficiently and on schedule.

Production Plan: A production plan outlines the entire manufacturing process, ensuring that every step, from raw material sourcing to final product delivery, is executed efficiently and on schedule.

![]() Batching: Batching organizes fabrics into groups for processing. This step ensures consistency in treatment, whether for dyeing, bleaching, or finishing, helping maintain uniform quality across the batch.

Batching: Batching organizes fabrics into groups for processing. This step ensures consistency in treatment, whether for dyeing, bleaching, or finishing, helping maintain uniform quality across the batch.

![]() Bleaching: : Bleaching removes natural color and impurities from the fabric, preparing it for dyeing or further processing. This step ensures a clean, uniform base for achieving desired colors and finishes.

Bleaching: : Bleaching removes natural color and impurities from the fabric, preparing it for dyeing or further processing. This step ensures a clean, uniform base for achieving desired colors and finishes.

![]() Dyeing: Dyeing imparts color to the fabric, using various techniques to achieve the desired shade and pattern. This process is vital for creating vibrant, appealing textiles that meet design specifications.

Dyeing: Dyeing imparts color to the fabric, using various techniques to achieve the desired shade and pattern. This process is vital for creating vibrant, appealing textiles that meet design specifications.

![]() Finishing: Finishing enhances the fabric’s texture, appearance, and performance by applying treatments like softening, waterproofing, or flame retardance. This final touch ensures the fabric meets quality standards.

Finishing: Finishing enhances the fabric’s texture, appearance, and performance by applying treatments like softening, waterproofing, or flame retardance. This final touch ensures the fabric meets quality standards.

![]() Inspection & Stocking (Finishing): Post-finishing, the fabric undergoes a final inspection for quality assurance. Once passed, it is stocked and ready for cutting, sewing, or direct shipment.

Inspection & Stocking (Finishing): Post-finishing, the fabric undergoes a final inspection for quality assurance. Once passed, it is stocked and ready for cutting, sewing, or direct shipment.

Finishing:

![]() Cutting: Cutting is the process of precisely slicing fabric into pieces based on patterns. This step is crucial for minimizing waste and ensuring that each piece fits perfectly in the garment assembly.

Cutting: Cutting is the process of precisely slicing fabric into pieces based on patterns. This step is crucial for minimizing waste and ensuring that each piece fits perfectly in the garment assembly.

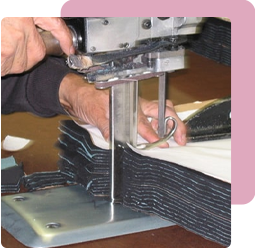

![]() Sewing: Sewing stitches together the fabric pieces, forming the garment. This skilled process requires precision to ensure a strong, neat finish that aligns with the design specifications.

Sewing: Sewing stitches together the fabric pieces, forming the garment. This skilled process requires precision to ensure a strong, neat finish that aligns with the design specifications.

![]() Embroidery: Embroidery adds decorative designs to the fabric or garment using thread, enhancing its aesthetic appeal. This artistic process adds value and uniqueness to the final product.

Embroidery: Embroidery adds decorative designs to the fabric or garment using thread, enhancing its aesthetic appeal. This artistic process adds value and uniqueness to the final product.

![]() Washing: Washing cleans the fabric or garment, removing impurities, excess dyes, or chemicals. This step ensures the product is soft, clean, and ready for the next stage of production.

Washing: Washing cleans the fabric or garment, removing impurities, excess dyes, or chemicals. This step ensures the product is soft, clean, and ready for the next stage of production.

![]() Inspection(Garments):After washing, garments are inspected for defects, ensuring they meet quality standards before moving to the final stages of production.

Inspection(Garments):After washing, garments are inspected for defects, ensuring they meet quality standards before moving to the final stages of production.

![]() Ironing/Folding:Ironing smoothens and shapes the garment while folding prepares it for packing. This step ensures the product looks polished and ready for presentation.

Ironing/Folding:Ironing smoothens and shapes the garment while folding prepares it for packing. This step ensures the product looks polished and ready for presentation.

![]() Packing & Stocking:Finally, garments are packed and stocked, ready for shipment or sale. Proper packing protects the products, ensuring they reach their destination in perfect condition.

Packing & Stocking:Finally, garments are packed and stocked, ready for shipment or sale. Proper packing protects the products, ensuring they reach their destination in perfect condition.

Advantages of ERP Software for Textile Garments & Apparel Industry

![]() Enhanced Inventory Management: An integrated ERP system for Textile automates stock operations, ensuring that the right products are delivered to stakeholders at the right time.

Enhanced Inventory Management: An integrated ERP system for Textile automates stock operations, ensuring that the right products are delivered to stakeholders at the right time.

![]() Improved Quality Control: Textile ERP software streamlines the entire production process, ensuring that finished products meet market quality standards. After passing quality checks, products are ready for shipment.

Improved Quality Control: Textile ERP software streamlines the entire production process, ensuring that finished products meet market quality standards. After passing quality checks, products are ready for shipment.

![]() Minimized Machinery Downtime: ERP for Textile, Garment and Apparel Industry optimize machine performance to maximize uptime, providing real-time data on machinery conditions for better management.

Minimized Machinery Downtime: ERP for Textile, Garment and Apparel Industry optimize machine performance to maximize uptime, providing real-time data on machinery conditions for better management.

![]() Efficient Supply Chain Management: Garment ERP software streamlines and tracks supply chains, which is especially valuable in global markets. It facilitates collaboration across departments for production and distribution.

Efficient Supply Chain Management: Garment ERP software streamlines and tracks supply chains, which is especially valuable in global markets. It facilitates collaboration across departments for production and distribution.

![]() Mobile Data Access and Security: As a cloud-based system, textile ERP software allows you and your team to access data securely from anywhere, eliminating the need to be physically present at the workplace.

Mobile Data Access and Security: As a cloud-based system, textile ERP software allows you and your team to access data securely from anywhere, eliminating the need to be physically present at the workplace.

![]() Enhanced Collaboration and Communication: ERP software for Apparel Industry fosters inter-departmental collaboration, a crucial aspect for any successful company, particularly in the textile industry.

Enhanced Collaboration and Communication: ERP software for Apparel Industry fosters inter-departmental collaboration, a crucial aspect for any successful company, particularly in the textile industry.

![]() Assisted Merchandise Management

Assisted Merchandise Management

![]() Seamless Payment and Receipt Handling: Textile ERP systems efficiently manage payments and receipts, processing large volumes of data quickly and generating detailed MIS and tax reports.

Seamless Payment and Receipt Handling: Textile ERP systems efficiently manage payments and receipts, processing large volumes of data quickly and generating detailed MIS and tax reports.

![]() Accurate Financial Reporting: ERP software for textile industry automatically generates real-time financial reports, providing businesses with precise and up-to-date account information.

Accurate Financial Reporting: ERP software for textile industry automatically generates real-time financial reports, providing businesses with precise and up-to-date account information.

![]() Boosted Sales:By analyzing past sales data, order quantities, and pricing, Garment ERP software helps to increase both current and future sales, carefully monitoring all aspects.

Boosted Sales:By analyzing past sales data, order quantities, and pricing, Garment ERP software helps to increase both current and future sales, carefully monitoring all aspects.

![]() Cost Reduction:ERP software for Textile and Garment boosts productivity and process efficiency, reducing labor costs by managing data on shift timings, tasks, and employee skills.

Cost Reduction:ERP software for Textile and Garment boosts productivity and process efficiency, reducing labor costs by managing data on shift timings, tasks, and employee skills.

With PACE360, jute industry players can overcome the challenges posed by manual processes and

fragmented systems, unlocking new levels of efficiency, productivity, and profitability.

empowered businesses to make informed decisions,

resulting in a substantial 18% growth in revenue within the first year of adoption.

Why Choose Pace360?

Unlocking the Power of ERP with Impactful Results

Cost Reduction

85%

Pace360 offers an 85% cost reduction compared to other prominent ERP Solutions, ensuring affordability without compromising functionality

User Satisfaction

98%

Navigate seamlessly through Pace360’s user-friendly interface, contributing to a remarkable 98% user satisfaction rate

Decision making Insights

100%

Take proactive decisions with PACE360’s insightful reports, dashboards and recommended alert-alarms

Modules Overview

Modules ERP Software for Textile Garments & Apparel Industry

Inventory Management

- Planning

- RFID-based Warehouse Management

- Multiple Inventory Valuation Methods (FIFO, Weighted Average, LIFO etc)

- Stock Inward/Outward

- Rejection Quantity Module

- Bin, Batch, Container, Drum Tracking

- Picking Automation

- In Process – Line, Rejection and Salvaging (ATR, RTA)

Production Planning

- Standard BOM/Project BOM Definition

- Material Requirement Planning (MRP)

- Alternate Bill of Materials (up to n’ levels)

- Auto Item code and Auto BOM generation

- MRP based on Forecast or Sales Order

- MRP (Auto Indent Generation / Bought – Out Schedule)

- MRP based Auto Purchase Order Generation

- Multi Stage Production Process Definition

Production Maintenance

- Machine – Operation Logging, Monitoring and Costing

- Fabrication, Maintenance, Tracking, Costing

- Tools (dies/moulds) Amortization

- Apportion (Excise, Fixed Asset, Life)

- Multi Stage Production Process

- Sub-Contractor In/Out (Job-Work)

- Machine Maintenance- Preventive, Scheduled, Predictive

- Loan Licensee

Sales & Distribution

- Pre-Sales Order (S.O.) Cycle (Enquiry / Quotation)

- Depot/C&F/C.A. & interface with HO+Works

- Field Management System closely interfaces with Headoffice.

- Sales Budget Calculation – (Product x Customer x Month x Quantity x Price)

- User Defined Sales Organization Structure

- Sales Price List Control Module

- Sales / Marketing Scheme

- Dispatch Order

Additional Modules

- HRM & Payroll

- Facial Recognition Attendance

- CRM Management

- Import & Export

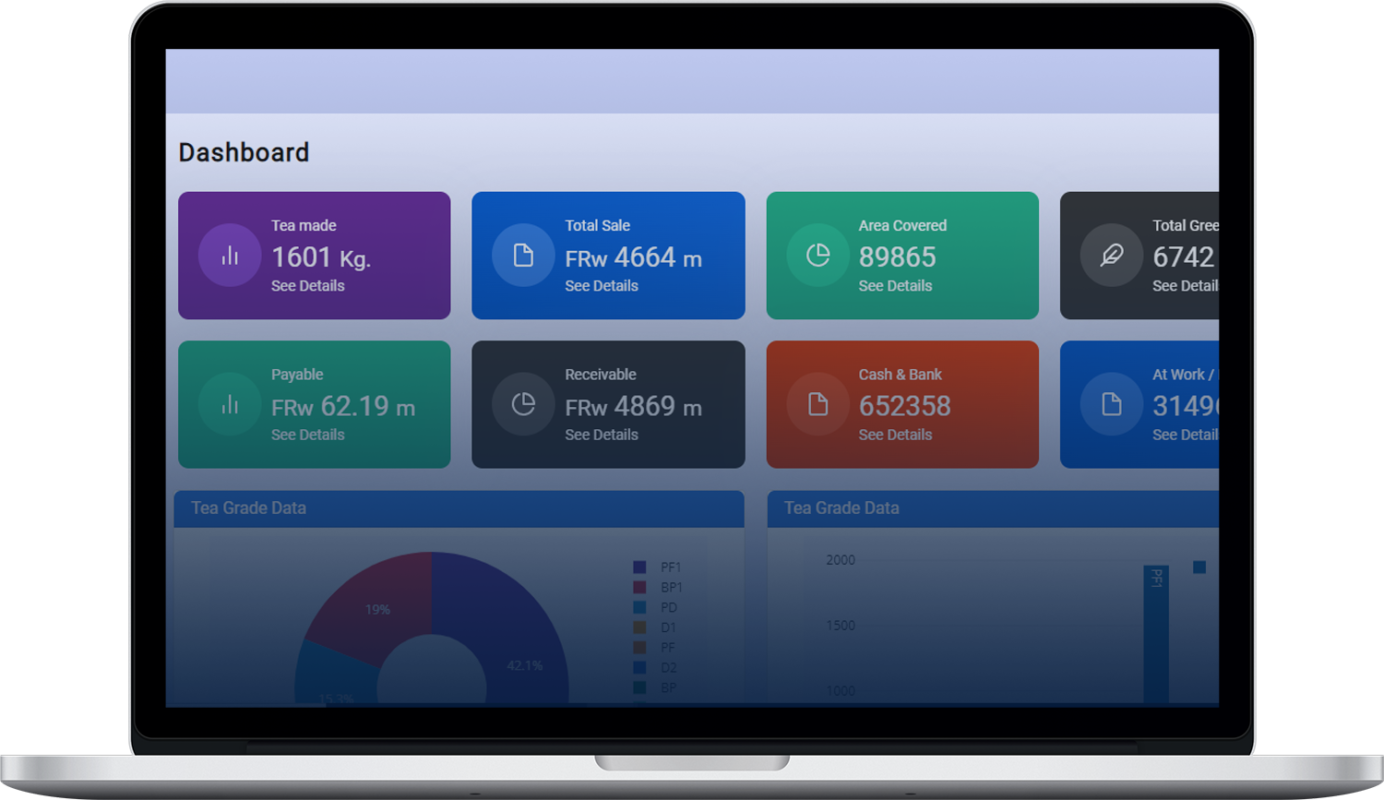

- User-friendly Dashboard

- Business Intelligence Reports

- Role-based Functional Rights

- Activity Alerts – SMS or Email

Overall Impact

-22%

Less Operational Cost

-23%

Less Administrative Cost

95%

On-time Delivery

Our Testimonials

What some of Our Clients saying

Frequently Asked Questions

A: Absolutely! Pace360’s customization allows it to cater to the unique needs of businesses of all sizes.

A: Yes, Pace360 seamlessly integrates with your current systems, ensuring a smooth transition with minimal disruption.

– Hassle-Free Installation –

Get Started In Three Simple Steps

Understanding Scope

Understanding business process and identification of key areas

Solution Implementation

Implement our solution seamlessly in your business enterprise

Success Unravels

Unravel your journey towards business growth & customer satisfaction with Softweb

– Real-Time Data Analysis

PACE360 Dashboard

It gathers, visualizes, and illustrates critical metrics from across the organization, offering deep insights into the performance by compellingly communicating with stakeholders a clear picture of their business in real time, thus resulting in more informed and timely business decisions.

PACE360 Dashboard is built in line with individual client’s corporate vision, operational managers’ hunger to monitor & demonstrate all small key metrics that counts, to ensure operational success, alert & alarm mechanism based on deviation in set metric to identify